Safety Policy

Basic Policy

SEKISUI KASEI Group prioritizes health and safety above all else, promotes safety activities with the objective of achieving zero accidents and zero incidents, and seeks to become a safe and secure company that is trusted by employees and society.

- 1. Creating a Safe and Secure Workplace

We promote the creation of a comfortable workplace environment in which all employees are healthy in both body and mind and feel that their work is worthwhile. - 2. Compliance

We comply with laws, regulations and ordinances related to health and safety, and security and disaster prevention, aiming a company trusted by society. - 3. Evolution of Safety Activities

Investigating danger and hazards in the working environment and reducing the risks with new perspectives without been obsessed with current condition, we continue to evolve our safety activities. - 4. Communication with Society

We aim good communication with authorities and local communities, and timely information disclosure. - 5. Education and Enlightenment

We aim rising awareness for the health and safety through enhancing educational and enlightenment activities and work on leveling up of every individual.

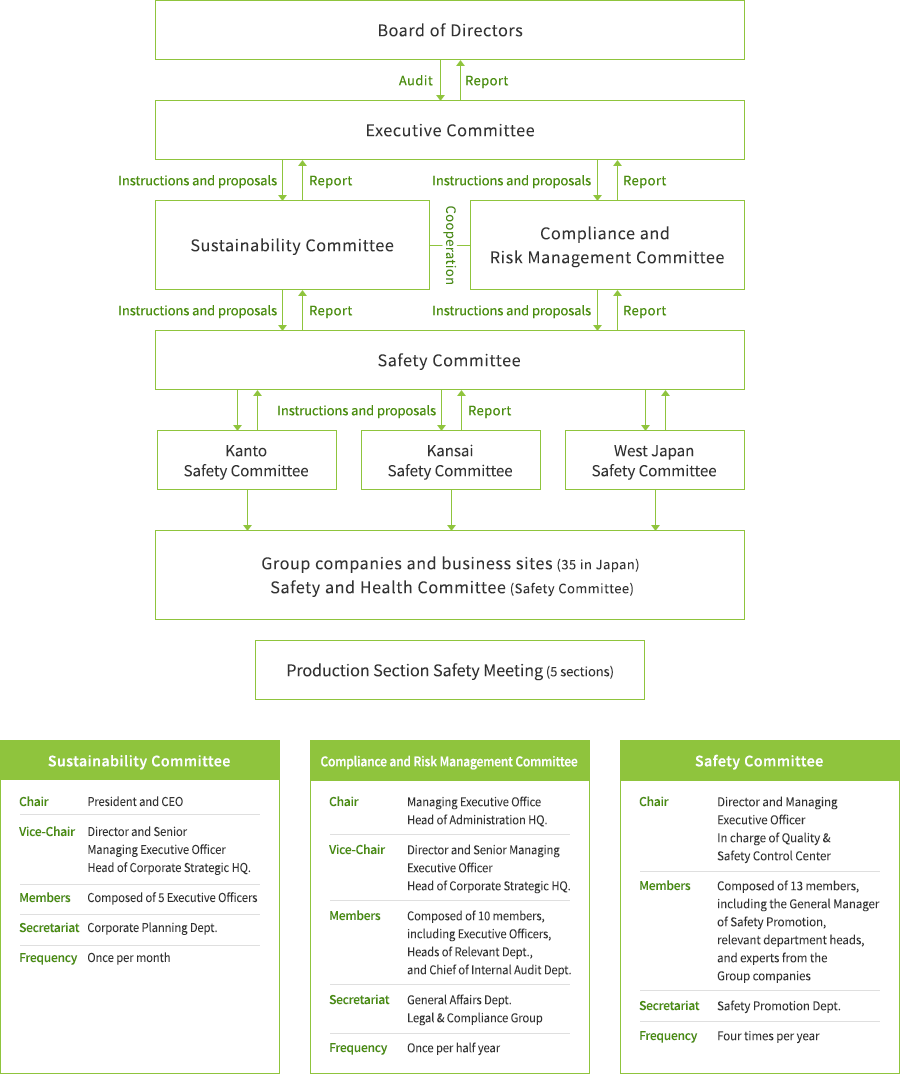

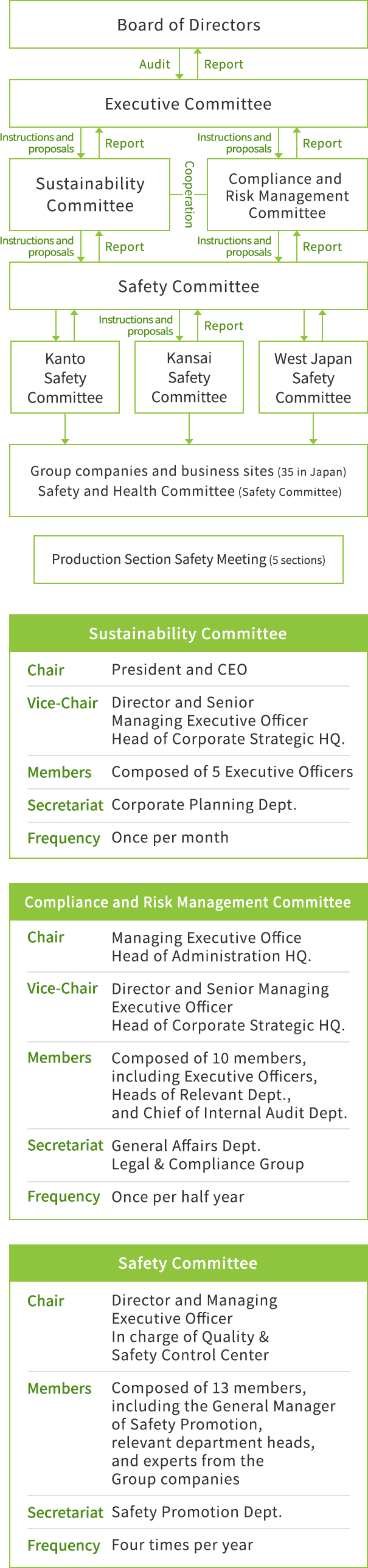

Safety Management System

Security Activities

In addition to workplace patrol by the top and safety patrol by the workers of each workplace, the following security activities are carried out.

-

【1】Interviews by the head of a workplace

The head of a workplace interviews with each individual worker. To grasp the behavioral characteristics of individuals quantitatively, the results of surveys on safety behaviors conducted by Japan Industrial Safety and Health Association are used for interviews in some workplaces.

-

【2】Designation of 'one day-safety leader'

'One day-safety leader' is designated in all group companies to raise people's sense of responsibilities and awareness of safety, and unsafe conditions are tried to be found and corrected.

-

【3】Meetings for safety in each production section

Group companies which have similar facilities and work procedures gather to propose safety measures for the facilities and work procedures and promote the implementation.

Obtaining ISO 45001 Certification

With regard to ISO 45001, the international standard for Occupational Health and Safety Management Systems (OH&S), Sekisui Kasei Tenri headquarters factory and Sekisui Kasei Tenri Okayama manufacturing department obtained this certification.

This represents 6% of all production facilities of SEKISUI KASEI Group in Japan.

Conducting Facility Safety Evaluations

SEKISUI KASEI Group evaluates potential risks in advance when planning the installation of facilities (new construction, modification, or alteration) for both new and existing businesses. By taking appropriate measures to address these risks, we conduct safety reviews based on the Guidelines for Equipment Safety Review to prevent accidents and disasters.

For each project, the Head of the Safety Promotion Department convenes experts as needed to conduct reviews of layout, processes, equipment, structures, and handled materials on-site, focusing on safety, health, environmental, and security aspects.

If any non-conformities are identified, the commencement of equipment operations may be delayed.

Additionally, during site audits conducted by the Responsible Care Self-Audit Committee, the status of recent equipment safety reviews, compliance with relevant regulations, and labor conditions are audited.

Labor Safety Targets and Performance Trends

SEKISUI KASEI Group promotes safety activities with the goal of achieving zero work-related accidents and has set the same target for FY2025.

In FY2024, the Lost Time Injury Frequency Rate (LTIFR) and Severity Rate were both lower than the manufacturing industry average (for companies with 100 or more employees), with the LTIFR at 0.31 and the Severity Rate at 0.003.

When accidents or work-related injuries occur, we conduct a thorough investigation to identify the causes, and implement safety measures from three perspectives: hard, soft, and human (mental and physical).

| FY2024 | FY2025 | ||

|---|---|---|---|

| Goals | Results | Goals | |

| Lost Time Injury Frequency Rate | 0.5 or less | 0.32 | 0.5 or less |

| Severity Rate | 0.05 or less | 0.059 | 0.05 or less |

*The five-years trends in the LTIFR and Severity Rate are included in our annually published integrated report.

Number of Work-related Accidents

The trend in work-related accidents within SEKISUI KASEI Group is shown below.

In FY2025, we aim to improve on the FY2024 results by striving for zero accidents and promoting company-wide initiatives to ensure a safe and secure workplace.

| Accidents | Death | Injury | |||

|---|---|---|---|---|---|

| Full-time Employees | Contract Employees | Full-time Employees | Contract Employees | ||

| FY2024 | 0 | 0 | 0 | 1 | 0 |

| FY2023 | 0 | 0 | 0 | 2 | 0 |

| FY2022 | 1 | 0 | 0 | 1 | 0 |

| FY2021 | 1 | 0 | 0 | 1 | 1 |

| FY2020 | 1 | 0 | 0 | 2 | 0 |

Safety Dojo (Training hall)

Safety Dojo (Training hall) is established in 11 workplaces in Japan and 5 workplaces in overseas, where the simulation of accidents can be experienced as an educational facility to increase workers' awareness and skills for safety. Safety Dojo is used by all the employees for regular safety trainings to learn safety behaviors and education by using simulation facilities.

Holding Health and Safety Committees

SEKISUI KASEI Group has established Health and Safety Committees at offices with more than 50 employees. These committees, which are held once a month, discuss labor safety and health issues between management and employees to promote improvements.

At offices with fewer than 50 employees, Health and Safety Promoters primarily listen to employees' requests and work to improve workplace safety and health standards.

Trainings for Emergency Treatment

SEKISUI KASEI Group carries out trainings for handling hazardous substances and high pressure gasses to prevent efflux accidents and fire drills regularly for full-fledged emergency treatment.

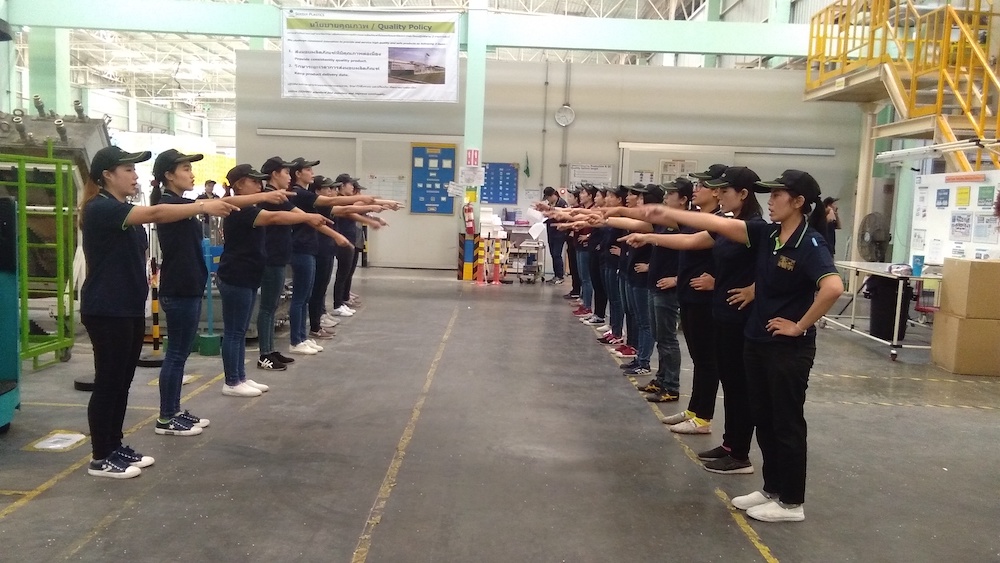

Safety and Health Activities

We provide regular safety education, workshops and trainings for employees to work safely, securely and healthily, and conduct risk assessment as part of risk prevention to eliminate or reduce potential risks and hazards in workplaces.